Pico-Solar Scorecard (Archived)

Green Building & Purchasing

Background

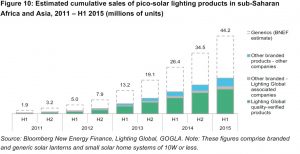

Nearly 1.3 billion people worldwide lack access to electricity, relying instead on  expensive and polluting fuels such as kerosene, wood, and coal for cooking and light. As solar PV became less costly, off-grid pico-solar products - devices under 10W - became available in these markets with more than 20 million products sold across Africa and Asia. These products offer a safer, cheaper, and more sustainable alternative to biomass and kerosene fuels for 89 million people; however, non-branded products now have equal pull in these markets putting market growth at risk due to inferior quality and lack of after-sales services.

expensive and polluting fuels such as kerosene, wood, and coal for cooking and light. As solar PV became less costly, off-grid pico-solar products - devices under 10W - became available in these markets with more than 20 million products sold across Africa and Asia. These products offer a safer, cheaper, and more sustainable alternative to biomass and kerosene fuels for 89 million people; however, non-branded products now have equal pull in these markets putting market growth at risk due to inferior quality and lack of after-sales services.

Little attention is being paid to pico-solar product disposal at end of life. Solar lanterns, for instance, have just a two - five year lifespan. Unfortunately, these products are not made for modularity and therefore components are generally not able to be replaced, recovered or recycled; in many cases, the products are simply burned or tossed aside. Moreover, communities without grid-access also tend to lack the infrastructure to safely process solar PV products at end of life. Toxic solar PV “e-waste” is already becoming a problem in the developing world.

Goals and Design

UCSC and the University of Edinburgh have joined together to create the Off-Grid Solar Scorecard to promote sustainable design and bring attention to solar PV products’ end of life. The project utilizes cradle-to-cradle, design-for-environment, and design-for-disassembly principles to assess products and assign them a grade for the three phases of the products’ life cycle. By partnering with widespread NGOs and distributors, we hope to influence manufacturers toward more sustainable design criteria with lower geopolitical risk, improved product performance and support to extend lifetimes through reuse, repair and recovery.

The Scorecard design team utilize Granta Design software to analyze and assign a grade for three product phases while incorporating performance evaluations from GOGLA, MIT and others for a more holistic assessment.

- Material Selection, Extraction, and Processing. This grade reflects the potential for risk due to material selection, incorporating geopolitical risk, toxicity, material durability, embodied energy, water, and CO2 footprint.

- Use: Performance and Repair. This grade is an assessment of the product use phase and includes performance and certifications, ease of disassembly and component replacement.

- End of Life: Circularity. This grade focuses on manufacturer support and transparency at end of life. Is the product under warranty? Does the manufacturer provide a take-back program or supply adequate information on recycling and disposal?